Operations Management Scheduling – Ambulance vs Procrastinator vs Hairdresser

What is Operations Management Scheduling?

Scheduling is about choosing the order in which tasks get done, specifically the sequence that resources get allocated for the creation or delivery of a product or service.

Scheduling is a core part of almost every industry’s operations; a car factory makes customized cars to order, a restaurant prepares the specific the meals ordered, a customer service help desk responds customer email questions, the Uber app has to decide which customer to pick up next, etc. The various rules that we use to set up schedules will depend on the nature of each business. Many of these have incredibly obvious solutions but the “obvious answer” can be very different in different industries and a minute disruption or extra factor can suddenly make it potentially very complicated.

Want to level up your Business Operations Management Fundamentals…

Checkout my 3hour introductory video training course: “Operations Management A-Z”

Operations scheduling examples: Deciding what gets done next

We’ve all been to a hair-dresser, their scheduling is quite obvious and familiar to us. Typically, whoever comes first gets their hair done first. Even if, instead they have an appointment system, it still fills up based on the first-come, first-served rule. Everyone understands the system, it’s easy and fair, and customers can’t get angry. From the hairdresser’s perspective, finishing one customer’s hair is just as good as another’s, they all pay roughly the same amount. It’s a great scheduling system, optimized for fairness and simplicity.

How about an ambulance? An ambulance is a valuable operational resource that can be allocated to urgent “jobs” at short notice to deliver a rather crucial “service”. When an emergency call reaches a dispatcher, they will allocate and send an idle ambulance to help. So far, sounds pretty simple? Well, not so quickly. Just like any important productive resource in operations, be it a machine, a skilled person / team or a budget allocation; if a more important “job” / project comes along, there is a strong case to divert those resources. This certainly makes sense in the case of an ambulance. If one is already driving to an emergency when another, more urgent emergency comes in over the phone, another resource allocation decision needs so made. In this particular case, we all understand that it’s generally sensible for the dispatcher to divert the ambulance from the initial emergency and send it to the more pressing one. But then, what happens if the ambulance has already arrived at the initial location and has already started providing emergency care? Should they simply quit halfway through and go to the more urgent emergency? The initial seemingly obvious and simple scheduling decision has gotten quite complex. Add in other factors such as lack of perfect knowledge on the severity and risk of the emergency, different distances to drive, traffic, age and insurance status of the patients and the range of things that could be considered become immense.

DISCOVER THE “FORGOTTEN FUNDAMENTALS” OF OPERATIONS MANAGEMENT”

Dispatchers have to make scheduling / resource allocation decisions that save lives and risk death, and they base this decision-making process on both, their highly trained medical assessment abilities, using all the available information meanwhile strictly working within a well-defined, set of rules. These rules are essential, as it would be crippling to leave the mental and moral burden of considering every factor on the shoulders of an individual dispatcher.

Certainly, in the ambulance case, dispatchers have to be very careful about when committed their resources to a job at all as it creates large costs and complications in case a more urgent, more important, or more profitable job comes up at short notice…

Take away the incredibly high stakes of life and death and this is the exact same kind of scheduling decisions that an operations manager has to make in a factory. Do we set up the special machine to run a new, small customer order? But then, if another more profitable, more urgent order is required, we have to decide whether we abandon our current order for the more profitable / more urgent one. Alternatively, we persist with our current job and risk losing an important customer by failing their urgent order. Scheduling is all about tradeoffs, and they are rarely easy decisions.

Every day you sit down at your desk and write down a little to-do list, and then decide which one to do first. Perhaps unwittingly, you’re actually scheduling yourself. Do you do the oldest task first? First in, first out. Or do you like to focus on the easiest ones first, to get a good string of victories to start the day? Or perhaps you pick the task that will have the most benefit to your company in the long term? Or maybe what is best for your career in the long term? All of these decisions are scheduling decisions based on an internal set of rules to optimize for a certain objective.

Types of operations management scheduling

Operations managers can optimize their scheduling for a specific outcome / objective in several ways:

- Optimizing for fairness, ease, and transparency by using the “first-come-first-served” rule.

- Optimizing for short-term, greatest number of jobs completed, doing the easiest / shortest jobs first.

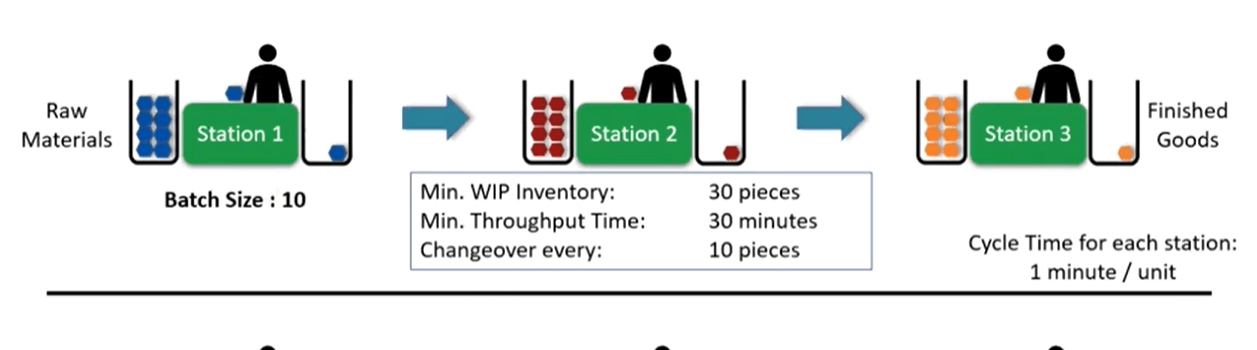

- Optimizing for medium-term maximum output by minimizing changeovers.

Keep in mind that these are just some of the possible objective and scheduling methodologies to achieve it. There are many more different ways to do so depending on the goals and circumstances of the business, and they have a huge impact on the overall performance of the organization.

What is operations management scheduling?

Scheduling in operations involve planning the sequence of jobs to create and deliver products and services. This requires the deliberate allocation of resources in a certain order to achieve them and ideally creating a clear and consistent set of rules or guiding principles about how they get allocated.

Job Scheduling can be optimized for different outcomes, for example, most jobs completed, maximizing output quantity long term or satisfying the loudest shouting customers….

Want to level up your Business Operations Management Fundamentals…

My video training course: “Operations Management A-Z”

Crack On!