Safety Stock Calculation Inventory Control

Course Reviews

Yes. This is good and helps a whole lot. It actually makes one think outside of the box especially that which have been used to for a long time. It brought about a whole broad of knowledge about logistics and supply chain mgt.

I am enjoying the course very much. Great instructor, clear, concise, voice is at the perfect pace.

Quickly paced yet gets into many core / foundational elements Would benefit introducing newer tech opportunities available for SC

Superbly presented, with a great pace. Excellent explanations and visuals, and Laurence's style was engaging and kept me interested throughout. I would recommend this to anyone wanting a real good introduction to OM.

This course in Operations Management, I considered it to be excellent; all the shared knowledge was extremely well explained, insightful and highly applicable; the resources are very useful, clear and well explained. I really enjoyed the course very much. Thank you, Laurence Gartside, and Udemy. Crack on!

I am starting a business and had very little idea on inventory management. Laurence did a great job explaining the fundamentals and tools I can use to measure my performance and manage my inventory better. Concepts were clear and easy to understand. I don't think you really need any prior knowledge. Recommended and will take a future course!

Fantastic course! Laurence was engaging from the very first lecture. The examples used, his lively presentation style and goofy jokes make for an very entertaining watch, all the while covering a lot of content in detail. I particularly enjoyed the examples about the Rolls Royce airplane jets and barrels of whiskey! I will definitely be signing up for more of his courses. The content is clearly and concisely illustrated in a very engaging manner. I could not recommend this course more highly!

Laurence has a unique way of explaining complex concepts very easily. This is a must for those that are new in the logistic industry. Absolutely recommended.

This module is very informative. A lot of very good information given on the LEAN process. The facilitator is very knowledgeable and provides a lot of very good information. Very worthwhile watch if you are looking for more information on the LEAN process.

I Finished The Course Today as a person with basic knowledge of KPI's this Course covered what it promised Mr. Laurence was clear enchanting and considerate of repeating the critical information easily grabed attained my attention the whole course with quizzes and Funny memes :) Thank you

The course is very well structured and organized. Laurence is explaining the subject very clearly and systematically and building up the knowledge in a very engaging and logical manner. Very highly recommended!

I love the detailed explanations and further given depth of each topic. I'm learning for work and your videos have boosted my overall understanding of my duties + future.

The course was very informative and is also a good refresher. It is well paced, well explained, great overview and good value when breaking things down as well. The instructor is clearly knowledgeable and explains things quite coherently. The videos/lectures are broken down into easy-to-digest chunks and I got to learn a lot of new concepts. Would definitely recommend to anyone looking to form a knowledge base on supply chain management.

Mr. Gartside is an engaging and entertaining instructor. The short sessions make it easy to fit the course into any schedule. I am new to the Inventory Control world, and was immediately able apply what I learned to the "real world". I look forward to taking another course by this instructor.

His courses are very well laid out. the concepts are clearly explained and woven together to paint a clear holistic picture of the subject at hand. I bought the Inventory Control course and had to get this one!!

Course Content

Optimize your Supply Chain Safety Stock. Simple to Advanced Methods. Reduce Costs and Risk in your Business Operations

Requirements

- High School Maths (Age 17 ish)

- Basic Microsoft Excel

- A desire to save a ton of money through your robust inventory management!

- High tolerance for dubious humour

Description

This MBA style course prepares and empowers you to calculate and control your Safety Stock. A crucial area of Inventory Management.

The eternal question: How to balance the risk of stock-outs with the quantity of safety stock inventory held?...

We cover 3 methods to calculate your Safety Stock - from super simple to advanced statistics:

Method 1: Number of Days of Safety - A fast and very basic method to get a quick decision

Method 2: HiHi-AvAv (my own name for a very established method ;) Finding the difference between our high "Lead Time Demand" and the average to determine the level of cover we want from periods of high demand during a slow replenishment lead time.

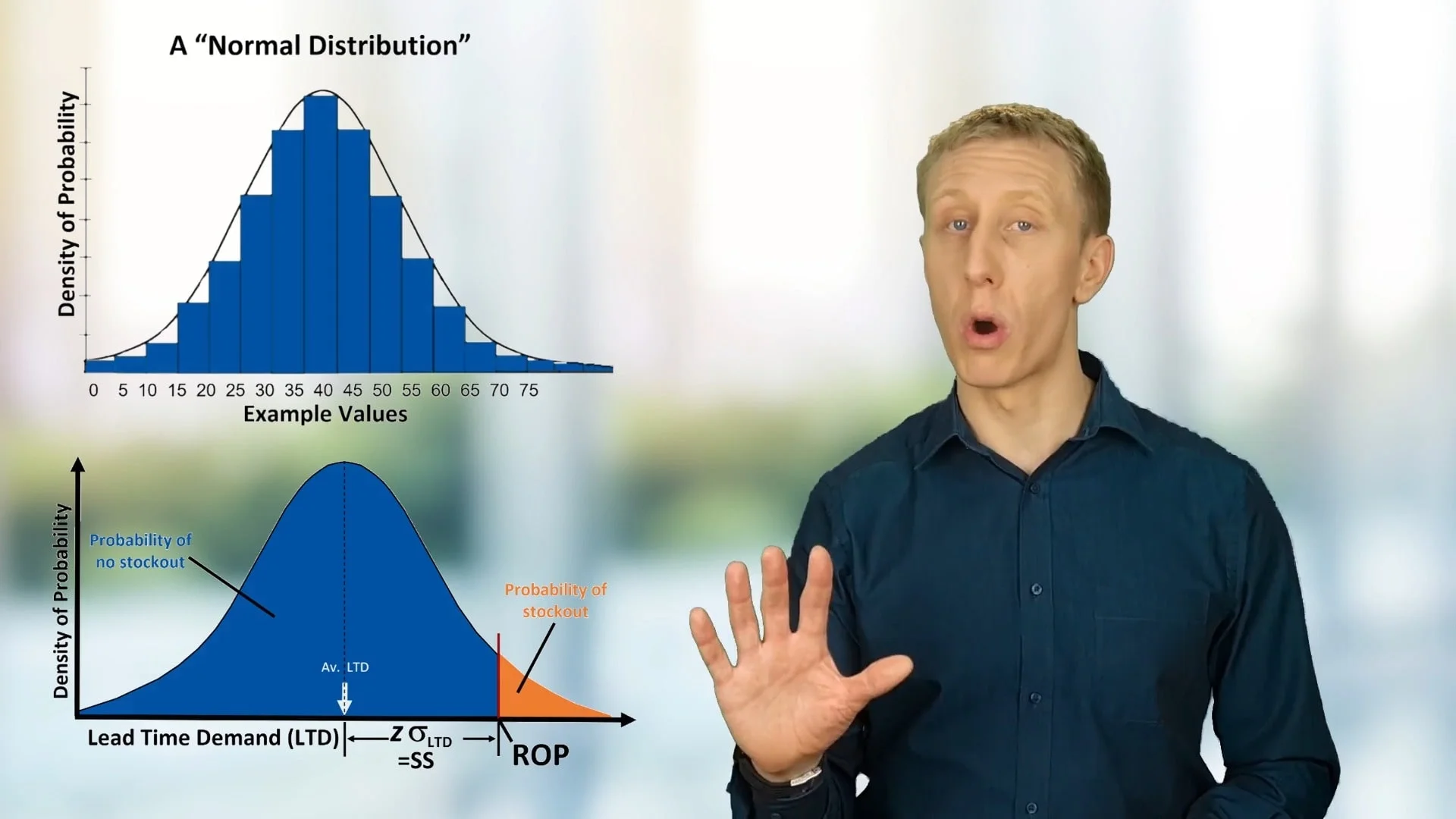

Method 3 : Statistical Method - The most rigorous method. We model our "Lead Time Demand" as a "Normal Distribution", determine our desired "Service Level" (acceptable risk of a stockout) and use a little help from some excel formulas to calculate our required Safety Stock and Re-Order Point quantity.

Course Sections:

1. Inventory Control Introduction

2. Safety Stock Background

3. Inventory Dynamics

4. Simple Safety Stock Calculations

5. Calculating Safety Stock using Statistics

6. Getting Your Data

7. Assumptions and Limitations of the Statistical Method

8. Fixed Lead Time, Variable Demand: Method 3 Continued

9. Variable Lead Time and Demand: Method 3 Continued

10. Choosing your Service Level - Your Tolerance for Risk

11. Probability of a Stockout Over Time - Calculating Risk

12. Optimizing Safety Stock Levels

13. Conclusion

14. Bonus and Appendix

This course is for dedicated operations manager, the ambitious procurement professionals, the striving logistics supervisors, hands-on production planners and the practical business optimization analysts.

- Remove the guesswork and add structure to your crucial safety stock decisions.

- Take control of your inventory management to have and "impact" and "improve" your business operations - manufacturing, services, industrial operations and production.

- Equip yourself to take a new leading role in your workplace - improving your processes, systems & business / organization.

- Quantify your risk, calculate your inventory requirements and articulate your method - removing the guesswork and fearful overstocking

Downloadable Summary PDF Documents - throughout the course

Almost all businesses have inventory: retail stores, factories, hospitals, hotels, car repair, warehousing, logistics and more - this means we all have to decide how much to hold and when to place an order from the suppliers for more. Place the order too late and, with a little extra demand than usual, you might stockout! Carry too much inventory and you pay for it in holding and financing costs every day, quietly sucking the profit from your business and crippling your cashflow and investment opportunities.

Having enough stock available whilst minimising costs and risk is the fundamental balance that can determine your business's success. Getting a strong control and continuously improving your business operations is essential to remain competitive, improving profitability, improving customer experience and customer satisfaction, reducing costs and improving delivery.

Without a solid grasp of safety stock and methods of calculation; no operations manager, can competently or confidently manage their risk without excessive costs.

Be the one bringing clarity and structure to this most crucial decision!

Specific Topics Covered in the Course:

- Why we need Safety Stock

- Consequences of Stockouts

- Costs of Inventory

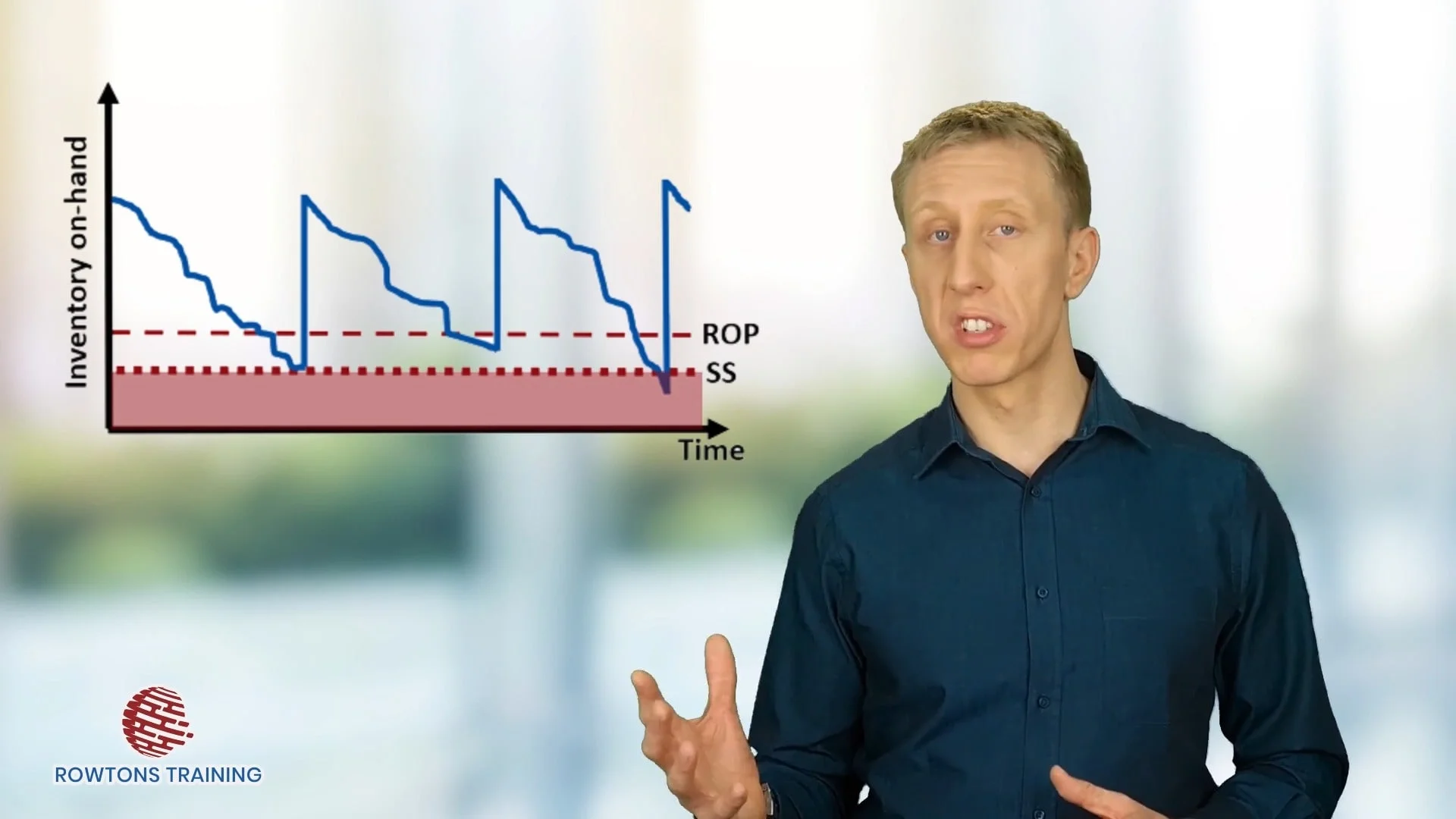

- Inventory Dynamics

- Quick Calculations of Safety Stock

- Rigorous Statistical Method to calculate Safety Stock

- How to Model your "Lead Time Demand"

- How to Determine your own desired "Service Level"

- What the Probability of having a Stockout in a given period of time

- How we can Reduce our Need for Safety Stock

- Alternatives to holding Safety Stock

Take control! Boost your career and your business! Start learning today!

Laurence Gartside

- Operations Management

- Lean Manufacturing

- Supply Chain

- Logistics & Transportation

- Business Performance

- Manufacturing Improvement

Safety Stock Calculation Inventory Control

This course is for dedicated operations manager, the ambitious procurement professionals, the striving logistics supervisors, hands-on production planners.

Course Hours

2.5

Lessons

66

Study Level

All Levels

Course Price

$149.95

Optimize your Supply Chain Safety Stock. Simple to Advanced Methods. Reduce Costs and Risk in your Business Operations

Requirements

- High School Maths (Age 17 ish)

- Basic Microsoft Excel

- A desire to save a ton of money through your robust inventory management!

- High tolerance for dubious humour

Description

This MBA style course prepares and empowers you to calculate and control your Safety Stock. A crucial area of Inventory Management.

The eternal question: How to balance the risk of stock-outs with the quantity of safety stock inventory held?...

We cover 3 methods to calculate your Safety Stock - from super simple to advanced statistics:

Method 1: Number of Days of Safety - A fast and very basic method to get a quick decision

Method 2: HiHi-AvAv (my own name for a very established method ;) Finding the difference between our high "Lead Time Demand" and the average to determine the level of cover we want from periods of high demand during a slow replenishment lead time.

Method 3 : Statistical Method - The most rigorous method. We model our "Lead Time Demand" as a "Normal Distribution", determine our desired "Service Level" (acceptable risk of a stockout) and use a little help from some excel formulas to calculate our required Safety Stock and Re-Order Point quantity.

Course Sections:

1. Inventory Control Introduction

2. Safety Stock Background

3. Inventory Dynamics

4. Simple Safety Stock Calculations

5. Calculating Safety Stock using Statistics

6. Getting Your Data

7. Assumptions and Limitations of the Statistical Method

8. Fixed Lead Time, Variable Demand: Method 3 Continued

9. Variable Lead Time and Demand: Method 3 Continued

10. Choosing your Service Level - Your Tolerance for Risk

11. Probability of a Stockout Over Time - Calculating Risk

12. Optimizing Safety Stock Levels

13. Conclusion

14. Bonus and Appendix

This course is for dedicated operations manager, the ambitious procurement professionals, the striving logistics supervisors, hands-on production planners and the practical business optimization analysts.

- Remove the guesswork and add structure to your crucial safety stock decisions.

- Take control of your inventory management to have and "impact" and "improve" your business operations - manufacturing, services, industrial operations and production.

- Equip yourself to take a new leading role in your workplace - improving your processes, systems & business / organization.

- Quantify your risk, calculate your inventory requirements and articulate your method - removing the guesswork and fearful overstocking

Downloadable Summary PDF Documents - throughout the course

Almost all businesses have inventory: retail stores, factories, hospitals, hotels, car repair, warehousing, logistics and more - this means we all have to decide how much to hold and when to place an order from the suppliers for more. Place the order too late and, with a little extra demand than usual, you might stockout! Carry too much inventory and you pay for it in holding and financing costs every day, quietly sucking the profit from your business and crippling your cashflow and investment opportunities.

Having enough stock available whilst minimising costs and risk is the fundamental balance that can determine your business's success. Getting a strong control and continuously improving your business operations is essential to remain competitive, improving profitability, improving customer experience and customer satisfaction, reducing costs and improving delivery.

Without a solid grasp of safety stock and methods of calculation; no operations manager, can competently or confidently manage their risk without excessive costs.

Be the one bringing clarity and structure to this most crucial decision!

Specific Topics Covered in the Course:

- Why we need Safety Stock

- Consequences of Stockouts

- Costs of Inventory

- Inventory Dynamics

- Quick Calculations of Safety Stock

- Rigorous Statistical Method to calculate Safety Stock

- How to Model your "Lead Time Demand"

- How to Determine your own desired "Service Level"

- What the Probability of having a Stockout in a given period of time

- How we can Reduce our Need for Safety Stock

- Alternatives to holding Safety Stock

Take control! Boost your career and your business! Start learning today!

Course Content

Safety Stock Calculation Inventory Control

Optimize your Supply Chain Safety Stock. Simple to Advanced Methods. Reduce Costs and Risk in your Business Operations

Requirements

- High School Maths (Age 17 ish)

- Basic Microsoft Excel

- A desire to save a ton of money through your robust inventory management!

- High tolerance for dubious humour

Description

This MBA style course prepares and empowers you to calculate and control your Safety Stock. A crucial area of Inventory Management.

The eternal question: How to balance the risk of stock-outs with the quantity of safety stock inventory held?…

We cover 3 methods to calculate your Safety Stock – from super simple to advanced statistics:

Method 1: Number of Days of Safety – A fast and very basic method to get a quick decision

Method 2: HiHi-AvAv (my own name for a very established method 😉 Finding the difference between our high “Lead Time Demand” and the average to determine the level of cover we want from periods of high demand during a slow replenishment lead time.

Method 3 : Statistical Method – The most rigorous method. We model our “Lead Time Demand” as a “Normal Distribution”, determine our desired “Service Level” (acceptable risk of a stockout) and use a little help from some excel formulas to calculate our required Safety Stock and Re-Order Point quantity.

Course Sections:

1. Inventory Control Introduction

2. Safety Stock Background

3. Inventory Dynamics

4. Simple Safety Stock Calculations

5. Calculating Safety Stock using Statistics

6. Getting Your Data

7. Assumptions and Limitations of the Statistical Method

8. Fixed Lead Time, Variable Demand: Method 3 Continued

9. Variable Lead Time and Demand: Method 3 Continued

10. Choosing your Service Level – Your Tolerance for Risk

11. Probability of a Stockout Over Time – Calculating Risk

12. Optimizing Safety Stock Levels

13. Conclusion

14. Bonus and Appendix

This course is for dedicated operations manager, the ambitious procurement professionals, the striving logistics supervisors, hands-on production planners and the practical business optimization analysts.

- Remove the guesswork and add structure to your crucial safety stock decisions.

- Take control of your inventory management to have and “impact” and “improve” your business operations – manufacturing, services, industrial operations and production.

- Equip yourself to take a new leading role in your workplace – improving your processes, systems & business / organization.

- Quantify your risk, calculate your inventory requirements and articulate your method – removing the guesswork and fearful overstocking

Downloadable Summary PDF Documents – throughout the course

Almost all businesses have inventory: retail stores, factories, hospitals, hotels, car repair, warehousing, logistics and more – this means we all have to decide how much to hold and when to place an order from the suppliers for more. Place the order too late and, with a little extra demand than usual, you might stockout! Carry too much inventory and you pay for it in holding and financing costs every day, quietly sucking the profit from your business and crippling your cashflow and investment opportunities.

Having enough stock available whilst minimising costs and risk is the fundamental balance that can determine your business’s success. Getting a strong control and continuously improving your business operations is essential to remain competitive, improving profitability, improving customer experience and customer satisfaction, reducing costs and improving delivery.

Without a solid grasp of safety stock and methods of calculation; no operations manager, can competently or confidently manage their risk without excessive costs.

Be the one bringing clarity and structure to this most crucial decision!

Specific Topics Covered in the Course:

- Why we need Safety Stock

- Consequences of Stockouts

- Costs of Inventory

- Inventory Dynamics

- Quick Calculations of Safety Stock

- Rigorous Statistical Method to calculate Safety Stock

- How to Model your “Lead Time Demand”

- How to Determine your own desired “Service Level”

- What the Probability of having a Stockout in a given period of time

- How we can Reduce our Need for Safety Stock

- Alternatives to holding Safety Stock

Take control! Boost your career and your business! Start learning today!

Course Content

Course Content

Safety Stock Calculation Inventory Control

This course includes:

- 2.5Hours

- 66 Lessons

- All Levels

$149.95