Demand management plays a pivotal role in the strategic decisions of organizations across various departments. At its core, demand management involves the processes of demand forecasting and demand planning, aiming to predict and prepare for the future demand upon an organization’s operations. A proactive approach not only helps in determining the appropriate capacity needed but also minimizes the risk of unexpected surprises.

In this article, we’ll cover the fundamental concepts of demand forecasting and demand planning, and why they are crucial for organizational success.

What is demand forecasting?

Demand forecasting is about using all available information to estimate what the demand will be upon your operations in the future in the short, medium and long term. Demand forecasting and demand planning are essential for most departments of an organization: marketing, finance, supply chain, and operations, who have to make capacity-size decisions.

In the short term, this demand management may include planning some extra overtime, whilst in the long term, it might include building new factories.

Why is demand planning necessary?

Demand planning (looking ahead and estimating future demand) not only helps organizations plan the general level of capacity for a certain time period, but it also reduces the risk of being surprised.

While much demand variation is unpredictable to an extent, deliberate demand forecasting often can anticipate some future changes in demand and gives the organization time to prepare, rather than react and suffer.

Looking to learn more about demand and planning? The Rowtons Training Operations Management A-Z online course has a whole section dedicated to studying demand and capacity management. Browse the course topics and access free sample videos here.

Demand and forecasting: how does it work?

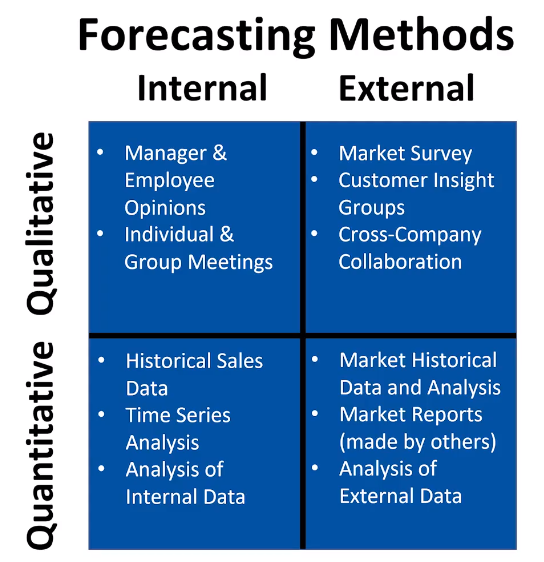

There are many methods of demand forecasting. We can show them with a two-by-two matrix, like the one below:

Organizations can use both internal and external methods of demand forecasting. This refers to where the information has come from, either within the organization (internal demand mgmt) or outside it (external demand mgmt). On the other side of the matrix, there are quantitative (numerical) and qualitative (non-numerical) methods.

Demand forecasting examples

- Internal quantitative demand forecasting method: time series analysis of historic demand data.

- Internal qualitative demand forecasting method: interviews with managers and analysts within the company for their predictions.

- External quantitative demand forecasting method: analysis of trends in the overall market data.

- External qualitative demand forecasting method: a market survey that gathers opinions of potential customers or people in other similar companies to share (non-sensitive) insights.

Demand and planning

Combining several of the above methods (external, internal, qualitative, quantitative) from multiple sources provides the best opportunity for a robust forecast. This is crucial to plan appropriate capacity for the short, medium, and long-term, and to reduce uncertainty and risk of upcoming, partially-predictable variation.

To get the value of a forecast, it should ideally be created collaboratively with input from many departments and then shared and communicated throughout the organization so everyone is working from the same assumptions and the same demand forecast.

If you want to expand your knowledge of demand and planning, then take a look at the Rowtons Training Operations Management A-Z online course. With an entire module dedicated to studying demand and capacity management, this operations management online course is the perfect way to deepen your understanding of this important topic.